Researchers Develop Lightweight Membrane Capable of Radically Reducing Inflight Noise

A strong, sound-proof membrane capable of radically reducing in-flight aircraft noise has been developed by a team of researchers.

Researchers at North Carolina State University, in cooperation with researchers at the Massachusetts Institute of Technology, have developed an innovative membrane which can greatly reduce the amount of noise entering an aircraft cabin.

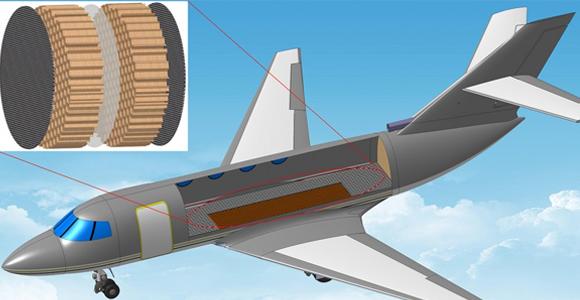

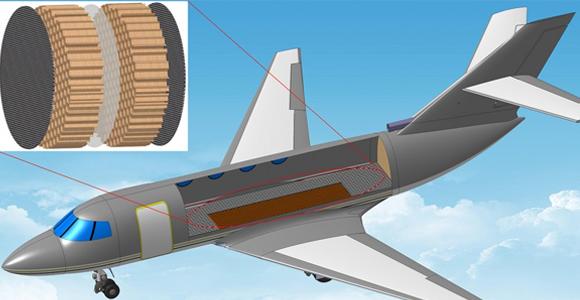

Most aircraft designers use light materials to make honeycomb structures for the floors and ceiling of aircraft cabins. When sandwiched together these honeycomb panels offer structure which are both strong and lightweight but which are notoriously poor at blocking sound.

The membrane, which is made of rubber only 0.25 millimeters thick, is designed to be stretched over one side of honeycomb structures in a drum like fashion. When a sound wave strikes the membrane, it tends to bounce off rather than pass through.

“The design is promising for making structures that are strong, lightweight and sound-proof” said Dr. Yun Jing, associate professor of mechanical and aerospace engineering at NC State.

According to Jing, the membranes are particularly effective with low frequency sounds, such as noise made by a jet engine. “At low frequencies — sounds below 500 Hertz, the honeycomb panel with the membrane blocks 100 to 1,000 times more sound energy than the panel without the membrane.”

While the membrane may be inexpensive to produce and its test results are impressive it has one significant drawback. In their paper “A lightweight yet Sound-proof Honeycomb Acoustic Metamaterial” the researchers observe that the membrane can add approximately 6 percent in overall weight. Airline operators may be reluctant to install the membranes it they add to overall costs or they become selective as to which cabins would get upgraded soundproofing.

[Photo: Yun Jing]